DIY Laser Engraving Plans for Beginners

31 Oct 2023

Are you hobbyists who are fond of customizing things with laser engraving machines, whether for wood or for metal or mug or something else? If your answer of the question is yes, please be with us to know more about DIY laser engraving.

Before you decide which technology to use for DIY, you must do some researches, which will render you enjoy excellent quality and affordable prices. In the following parts, you will be given some instructions about DIY laser engraving plans.

Table of Contents

Choices of Laser Engraving Machines for DIY

Safety Precautions for DIY Laser Engraving

Items You Want to Engrave

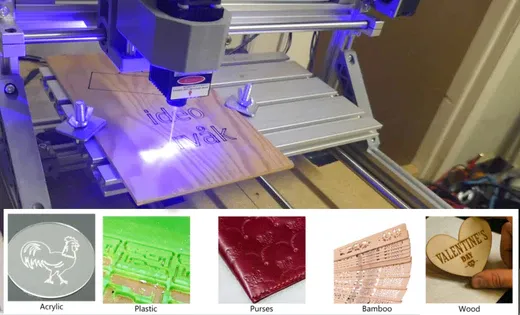

Whether you are a DIY laser engraving enthusiast or an entrepreneur who would like to develop in the laser engraving industry, the first thing to do before laser engraving is to figure out what you will engrave. For enthusiasts of DIY, considering the convenience and space factors, laser engraving machines can give you the best experience. For entrepreneurs who want to engrave a variety of objects, besides choosing laser engraving technology, a CNC engraving machine is also suitable. If you want to know more detailed and extensive introduction, you can read Reviews on 2023 CNCEST Engraving Machines.

If you are engraving on wood, you first need to figure out the material of wood, including softwood and hardwood. Some woods are easily vaporized by laser, such as birch, cherry or maple, which are easy to be engraved. For dense hardwoods, greater laser power is required when engraving or cutting. It is also recommended to use specialized engraving machine for wood, which is suitable for all types of wood. If you are interested in processing models, metal materials such as various signs, or engraving on some molds or handicrafts, you must choose a wide-applied laser engraving machine. The important thing is that you must control the laser engraving speed and power to get better engraving effect.

Choices of Laser Engraving Machines for DIY

After finding out what you want to engrave on, the following part you are caring about must be what laser engraving machine for DIY should be chosen. Don't care too much about the price when choosing a laser engraving machine. The most important thing is to ask the merchant whether the range of equipment that can be engraved meets your expectations. After all , hobbyists of DIY laser engraving are developing their interest in different stuff to engrave valuable information. Gone through different reviews, the following laser engraving machines have more advantages.

A. CNCEST Engraving Machine - Black 3018-pro with Laser Head 5500mw

Dimensions: 385 * 440 * 287 mm (L * W * H)

Worktable size: 300 * 180 mm (L * W)

The 3018 Laser Engraving Machine can engrave on plastic products, acrylic, wood flat relief. 0.3W-laser-head is suitable for paper and soft wood; 5W for paper, wood and plastic. The laser engraving machine, without complicated color matching, is designed in a minimalist style and is friendly to beginners of DIY laser engraving, for it is equipped with touch screen which is easy to use and monitor.

High-precision algorithm is adopted for stable and efficient operation and supported for high-speed operation. Equipped with a high-power laser module, the heat dissipation performance is good, and precision and speed are taken into consideration to make the engraving effect better. This powerful and operable laser engraving machine is an introductory learning mode, suitable for small amount of entertainment, DIY laser engraving or marking.

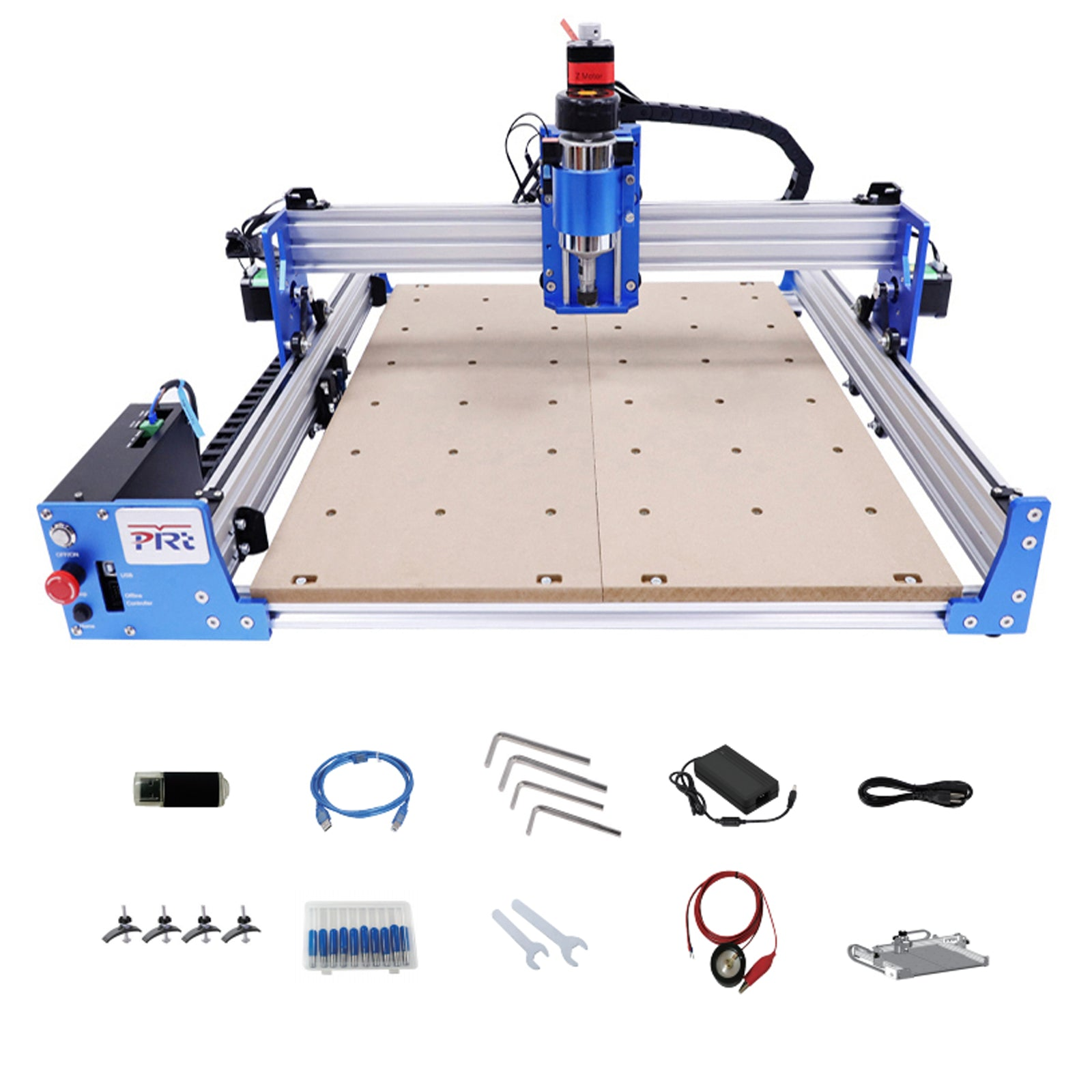

B. CNCEST USB Laser Engraving Machine

Engraving Area: 400 x 400mm/ 15.75 x 15.75 inches(LxW)

For enthusiasts of DIY with laser engraving machine, this USB Laser Engraving Machine, suitable for engraving on different kinds of material such as wood, MDF, acrylic, cardboard, vinyl, leather and so on, will definitely be your favorite. When you receive this portable laser engraving machine, you need to assemble the main components, without complicated installation, which is simple and easy to use as well as very suitable for beginners and professionals.

The 4040 laser engraving machine, adopting a new technology-Laser Beam Compression, can be a high-performance and fixed-focus laser, so that there is no need to adjust the focus before engraving. The focal spot of the new laser is 50% smaller than other ordinary lasers, which can not only achieve excellent performance, engrave more stably and durably, but also help to improve cutting efficiency for combining precision engraving and high-energy cutting.

Operating Methods

These laser engraving machines mentioned above can be compatible with various mature engraving software, such as Laser GRBL, Light Burn, and support Win XP, Win 7, Win 8 and Win 10. If you choose other engraving machines, you’d best to find out what software should be downloaded and install. Please follow the steps bellow to operate your laser engraving machines:

1.Download and install a driver and a software.

2.Assemble and locate the machine on steady desk well and make sure that your computer has a USB port output.

3.Connect the control box to the machine and your computer.

4.Follow the manuals, and use it step by step according to the instructions.

Safety Precautions for DIY Laser Engraving

A. Read the Manual

Every laser engraving is created so differently that it is necessary to read the manual provided by the manufacturer carefully and follow the assembly and safety instructions provided inside. Only by understanding the relevant instructions can you better operate it and avoid some accidents.

B. Avoid Fires

Under the right circumstances, you don't have to worry about fire if you are engraving on the supported material. However, it is recommended to have a fire extinguisher and a fire blanket in case of a fire. In some rare cases, a very small flame may begin during the process of engraving your material. If the flame without spreading is beyond 2 inches, it's best to put it out with a fire blanket. The most important thing is to turn off the laser engraving machine before trying to extinguish the fire. Once the laser machine is turned off and the nozzle is pushed away, throw your blanket onto the flames. If the flame larger than 2 inches spreads out, it should be put out with a fire extinguisher.

C. Protect Your Eyes

Any device that can emit lasers will require you to add additional protection to the existing equipment. While you are operating the laser engraving machine, it is best to wear appropriate laser goggles, which ensures your eyes from not hitting by the laser light directly. The degree of damage of the laser beam to the retina, lens or cornea is related to the exact position of the laser beam, the wavelength of the laser beam, the exposure time and the distance from the laser light source, etc. To wear goggles, therefore, is the best way to avoid this damage.

D. Clean the Laser Engraving Machine Regularly

Cleaning and maintenance at any time are necessary conditions for the normal operation of machines. After laser engraving for DIY, fragments of the material are likely to get stuck on the laser engraver, which may not only damage the machine and impair the quality of the item you are engraving, but also cause a fire seriously. Therefore, after each laser engraving project is completed, it is a good idea to vacuum clean the cutting deck and the internal cavity of the laser engraving machine.

Add Comments

Your Email Address Will Not Be Published. Required Fields Are Marked